gearbox cvt Fundamentals Explained

gearbox cvt Fundamentals Explained

Blog Article

On the other hand, some Nissan CVTs are actually identified to produce troubles connected to too much slipping. And a defective solenoid or interior transmission destruction could be the culprit behind this issue.

Some cone CVT layouts use two rollers.[23][24] In 1903, William Evans and Paul Knauf used to get a patent with a consistently variable transmission using two parallel conical rollers pointing in opposite directions and related by belts that would be slid alongside the cones to fluctuate the transmission ratio.

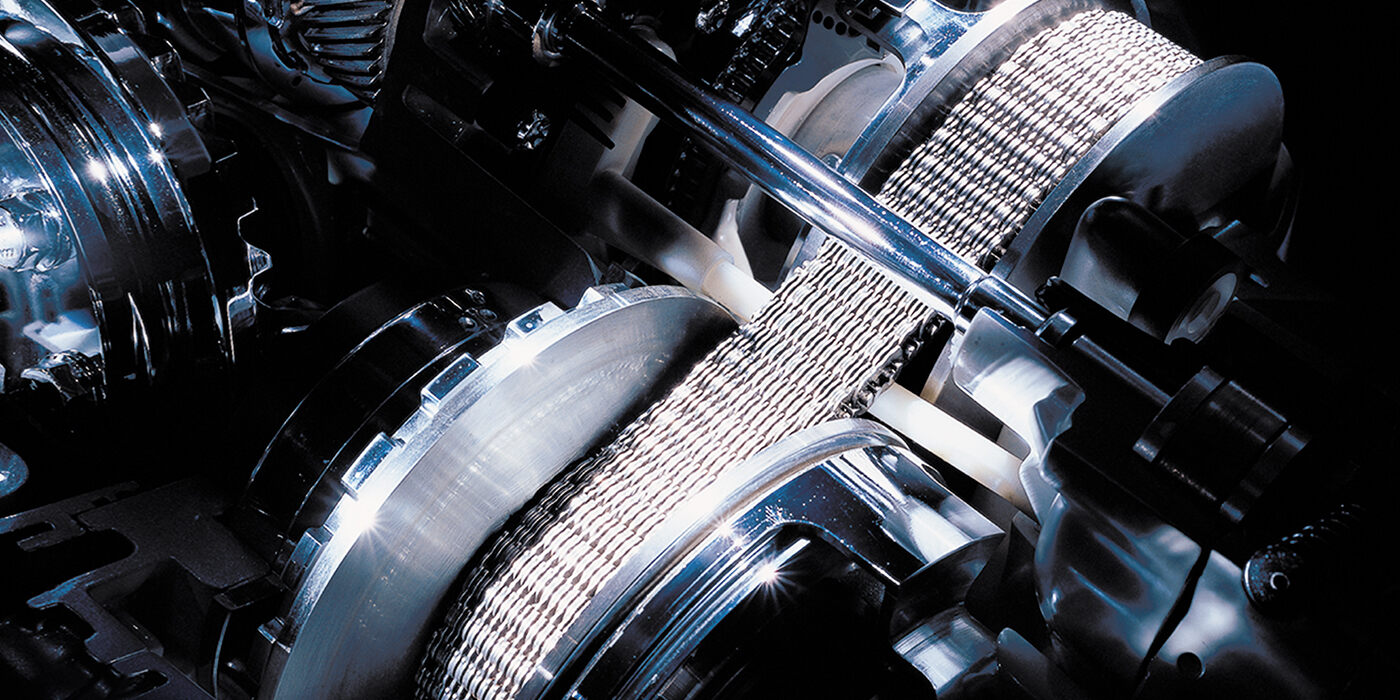

Such as, once the pitch radius is smaller within the driving pulley and enormous to the driven pulley, then the rotational pace from the pushed pulley decreases, resulting in a decrease “gear.” In the event the pitch radius is significant around the driving pulley and small to the driven pulley, then the rotational velocity of your pushed pulley will increase, causing a better “equipment.” Therefore, in principle, a CVT has an infinite number of "gears" that it may possibly run by at any time, at any engine or vehicle speed.

You may also have read some lousy rumors about CVTs and been warned off of these by your cousin’s brother’s Mate.

This can result in improved gasoline financial state as compared to standard automated transmissions. The CVT continuously adjusts the gear ratio to match the driving scenario, which may increase fuel performance.

A alter in gear ratios is realized through the variation of distance involving the pulleys as well as their variable diameter.

At the same time with this movement of input pulley, feeding output pulley (sheave) also moves and go from the fastened pulley which subsequently moves the part of the v-shaped belt wrapped round the output pulleys to the reduce cross-sectional Portion of the conical output pulleys and sought after pace ratio is attained.

This set up lets the engine to operate at its most productive velocity, offering improved gasoline overall economy and smoother acceleration. Due to the fact there are no distinctive gear improvements, you gained’t experience The standard ‘change’ seasoned in other transmissions.

Increasing the gap permits the cari di link ini belt to ride further while in the “groove”, Hence successfully lowering the pulley sizing. Reducing the gap has the other impact; the belt rides bigger, like in a larger pulley.

This 2nd type of layout is similar in principle to a pulley-centered CVT but nonetheless a little unique. The areas concerned Here's electricity rollers and discs, as an alternative to pulleys and belts. There are 2 disks involved with two rollers between.

Among the principal disadvantages of CVTs is they can often truly feel unresponsive or sluggish when accelerating from a quit. This is because the transmission takes time to regulate the pulleys and belt to the right ratio for your engine’s ability output.

The only form of cone CVT, the single-cone Variation, takes advantage of a wheel that moves along the slope of the cone, generating variation in between the slender and broad diameters on the cone.

CVTs may use hydraulic tension, centrifugal pressure or spring rigidity to generate the power needed to alter the pulley halves.

Weird noise (humming or whining) in the Nissan with CVT transmission is often produced that's because of many aspects like defective bearings or gears, a problem with CVT belts, or transmission fluid.